Why Choose an Auto Backwash Filter System?

- Prevents process/system downtime

- Minimizes operator exposure

- Cuts maintenance cost

- Reduces labor costs

- Eliminates filter element disposal and replacement cost

- Increases productivity

Self-cleaning filters represent the ideal situation and provide the most productive and labor free solution. Rosedale Products’ ABW is unique because our patented technology backwashes with a very low volume of liquid. This is achieved by using air pressure to create the shear velocity needed to effectively clean the filter element.

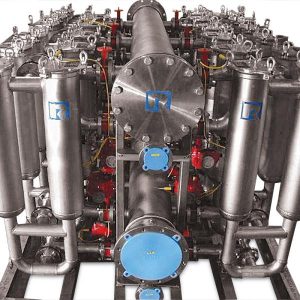

Flexible and Versatile Automatic Backwashing System

Flow rates from less than a hundred to several thousand GPM can be accommodated. Also, to meet footprint or space requirements, we can configure the systems as needed. Removal ratings from 5 micron and larger are available in a variety of filter media including standard bags, wire cloth and wedgewire. Continuous flow is maintained by taking one station at a time off-line for cleaning – the rest of the housings continue filtering.

Turnkey Systems for Backwashing Automatic System

Our systems have included air compressors, pumps, power distribution boxes, motor starters, climate controlled enclosures, heat trace and air dryers, all skid mounted and ready for installation

How an Automatic Self Cleaning Backwash Filter Works

Fluid is introduced through the lower portion of the filter housing. It is then flows through a filter element where the contaminant is captured on the outside surface. As clean fluid exits through the outlet, a controller monitors the differential pressure across the filter. When enough contaminant collects on the element and the differential pressure reaches a pre-selected point (^P), the backwash sequence is initiated. The backwash is accomplished by automatically shocking the filter with air or gas, which forces the liquid through the waste outlet. There is no introduction of additional fluids to contaminate the process, and the liquid discharged is only the volume of filter housing, thus reducing disposal costs. When the backwash operation is completed, the system returns on-line, the controller resets itself, and the whole process begins again. The backwash process lasts about 15 seconds.

Manually-controlled system minimizes operator exposure and backwash fluid – ideal for hazardous environments!

Backwashing Manual Filter System Features

- Prevents process/system downtime

- Minimizes operator exposure

- Cuts maintenance cost

- Reduces labor costs

- Eliminates filter element disposal and replacement cost

- Increases productivity

Our MBW manual backwashing filter uses standard 30 inch filter bags and baskets, providing over 600 square inches of filter surface area. The unit can be cycled through hundreds of backwashes before change-out is required. When pressure drop across the system is too great, indicated by the standard pressure gauges, the system is easily cycled through the backwash operation. Operation is simple. First close the valves for the inlet and outlet, then open the valve for the backwash outlet, which can be piped to a separate, safe location. Once that has been accomplished, simply depress the lever that shocks the system with clean air, causing the fluid in the housing to exit through the backwash outlet, removing the contaminant from the element at the same time. When the element is clean, usually in 30 seconds or so, simply return the three valves to their original positions to resume filtering.

Standard Features for the Manual Backwashing Filter System

- Permanently piped housings are opened without disturbing piping or requiring special tools

- Low-pressure drop

- Adjustable-height tripod legs

- 150 psi rated housing

- Pressure indicators for monitoring system efficiency

Standard Options for the Backwashing Manual Filtration System

- Carbon or stainless steel housings

- Seals of Buna-N, Ethylene Propylene, Fluoroelastomer, or PTFE

- 150 psi ASME code stamp

- Air eliminator