Download PDF (Manual)

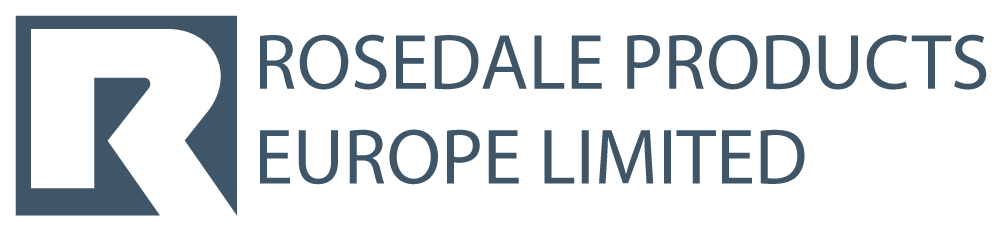

Standard Felt Filter Bags

Rosedale’s standard range of filter bags with ratings from 0.5 to 200 micron. Available in a variety of felt types and sizes for general use.

With galvanised carbon steel or stainless steel rings as options.

Download PDF (Manual)

High Efficiency Filter Bags

Our HI-E Series filter bags meet the most stringent needs for fine process. All are made of unique microfiber materials, designed to increase the efficiency and dirt holding capacity of the bag. Available in standard and high temperature materials. From 1 micron to 19 micron nominal.

Download PDF (Manual)

RPO / RPE Rosedale Specific Filter Bags

Download PDF (Manual)

Mesh Filter Bags - NMO / PEM

Monofilament mesh is a woven material where each thread is a single filament and the openings are square. Nylon or Polyester Mesh bags are available in 5 to 800 microns. NMO bags have excellent strength and are considered to be cleanable. Filter efficiency is 90% or more.

Download PDF (Manual)

High Temperature

Rosedale HT Series Meta Aramid Filter Bags are constructed of synthetic fibers that are extremely heat resistant. They can be used in applications to withstand intermittent temperatures as high as 464F/240C or continuous to 400F/204C.

Using a proprietary combination of fiber diameters, weights and thicknesses, HT Bags are an efficient depth filter media. To reduce fiber migration HT bags are glazed. For applications within the range of polyester (300F), the Rosedale RPE Flange top can be attached to provide an optimum seal. They are supplied with sewn seams, 1 to 200 microns with a nominal efficiency of 90%.

Download PDF (Manual)

Oil Absorbing - OA & OS

Our OA bag is ideal for removing trace oils and grease from coolants, waste water and many aqueous-based fluids. The OS filter bag is made of Rosedale’s proprietary polymer media providing for up to 10 times the hydrocarbon adsorption of OA Bags. They are used for many hydrocarbon adsorption applications and the OS Filter Bag is capable of removing free and dispersed oils as well as oil emulsions.

OA and OS are multi-layered bags manufactured with a media migration barrier and include reinforced lift handles to facilitate removal. They are rated at 25 microns.

Download PDF (Manual)

Graded Density

Our Graded Density series of filter bags meets the most stringent needs for today’s water, fine process, lubricant, food, and beverage filtration. Made of unique microfiber materials, they’re designed to increase the efficiency and dirt-holding capacities of the filter bag.

- Operates on the principle of depth filtration

- Filter grades of 1, 3, 8 and 19 microns @ 95% efficiency

- GD Bags are 100% polyester or polypropylene for excellent chemical compatibility

- FDA compliant to meet food grade government standards

Download PDF (Manual)

Beta Rated Bags

Rosedale Beta Bags® are unique multi layer filter bags made of polyester microfiber and encased in a spun-bonded media migration barrier. Evaluated by the ISO 4572 multi-pass test method, Beta ratings offer a true indication of performance throughout the life of the filter. This is significant because many filter ratings are based on initial efficiencies only. Beta Bags provide real ratings for the real world.

- Beta Bags® are 100% polyester for excellent chemical compatibility.

- All Beta Bags are available with Rosedale’s superior sealing RPE style flared top flange or as a ring type filter bag.

- Prevention of possible media migration is assured by the spun-bonded cover.

Download PDF (Manual)

XTND Filter Bags

XTND Filter Bags Offer Additional Surface Area for Increased Filtration Efficiency

Our XTND filter bag is a balance between increased efficiency and capacity versus cost. XTND filter bags offer 3 times the life of a standard bag. The flexible RP series plastic collar makes installation and disposal easier, as there is no metal to worry about. These bags are excellent for pre-filter and depth filter applications. If you’re looking for the ideal pre-filter or depth filter bag, try an XTND filter bag.

Requires a XTND Basket.

Download PDF (Manual)

Bag Sized Pleated Cartridges

These elements are easily installed in standard housings combining the best features of filter bags and cartridges into one single unit. Like bags they’re easily handled and trap contaminant internally to prevent “wash off”.

Like cartridges they provide greater surface areas and increased dirt holding capacities over a standard bag.

Special Application & Compatible Filter Bags

Rosedale Products Europe not only offer ranges of filter bags to suit Rosedale Housings. We are pleased to offer specialist manufacturing services for customised requirements and compatible patterns to other manufacturers designs. Our current portfolio extends to:

- PALL / FSI

- Eaton

- Strainrite

- Micron Technologies

- Krystil

- Filtration Systems

- Parker

Filter Bag Solutions

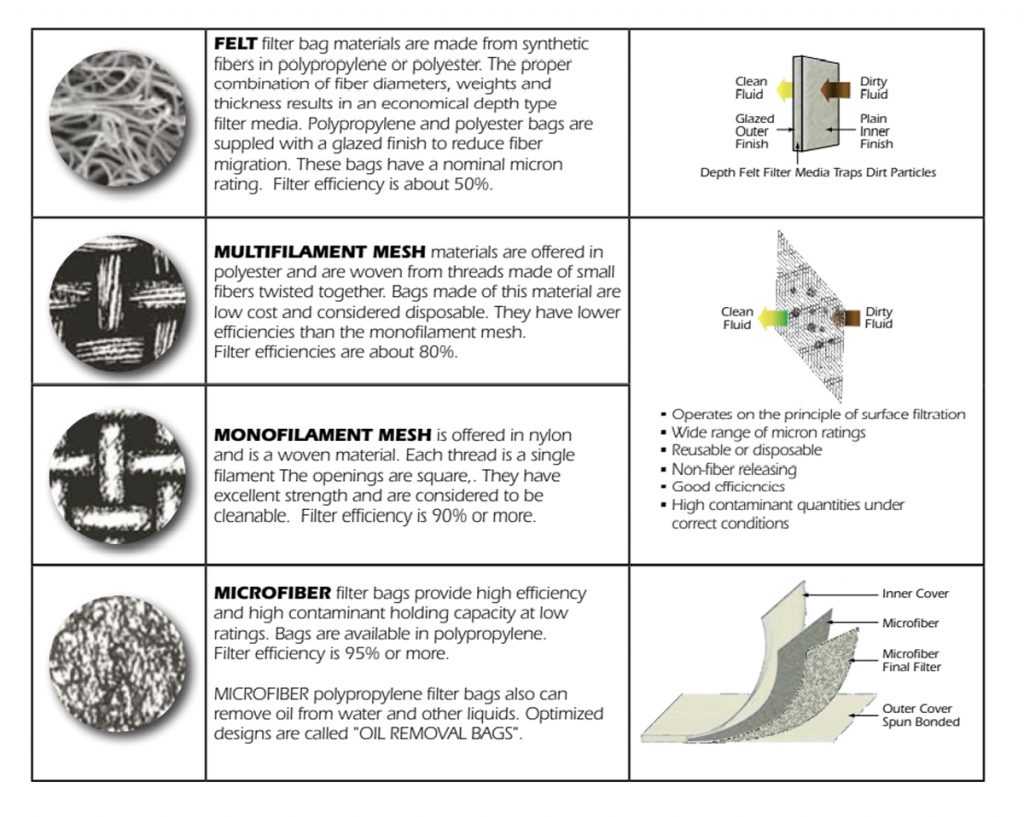

Filter bags can be the ideal solution for your industrial filtration application needs. They are designed to remove contaminant and debris from liquids and the dirt is caught inside the bag. Other filter technologies collect the solids on the outside of the device giving it the potential to dislodge into the filter upon removal. Filter bags keep the clean side of the filter that way, clean. The amount and size of contaminants the filter bags remove depends on their specific micron rating.

Filtration Levels for Filter Bags

Rosedale offers many levels of filtration to meet application criteria. We offer low-cost, standard efficiency filter bags and high-efficiency, high-capacity elements. Our standard capacity elements usually have about 4.4 square feet of surface area, holding approximately a pound of contaminant, perfect for many applications.

The filter bags we offer for this level of filtration include our standard filter bag, the Beta Bag®, and our RPO plastic top, self-sealing bag filter. These filter bags fit our standard side inlet housings.

Bag Filtration System Applications

Filter bags are used for a variety of industrial applications. These include:

- Construction materials industry

- Bio mass power stations

- Chemical and pharmaceutical industry

- Metal and steel production

- Coal-fired power stations

- Food industry

- Thermal waste treatment

- Hydraulic & Lubrication Industry

- Food & Beverage

- Industry

- Oil & Gas Industry

Liquid Filter Bag Solutions from Rosedale Products

Typically, our standard and pleated filter bags have from 5 to 25 square feet of surface area and hold from 1 to 11 pounds of contaminant. They offer a great balance between cost and capacity.Filter elements in this area of filtration include several unique designs. This features our X-Tend filter bag, the Graded Density filter bag, and our bag-sized Pleated Cartridge. All filter bags and cartridges will fit our standard housings, and offer features that Rosedale is famous for, such as keeping costs down