About the application

A new to market timber treatment created via chemical reaction requires high accuracy filtration to remove partially or unreacted elements of the production process which otherwise would continue to react and spoil the product in storage.

A particularly difficult solution to deal with as the individual raw elements of the final product each have very specific handling and compatibility requirements which was found to change dramatically post reaction stage of production.

Rosedale's Solution

In order to reduce production time and stabilize the finished product for prolonged storage (shelf life) the customer and Rosedale Products Europe have worked together through various stages of development targeting not only the very accurate requirement of the production process but also a requirement for fast and easy replacement, batch runtime lifespans and cost effectiveness for production price points.

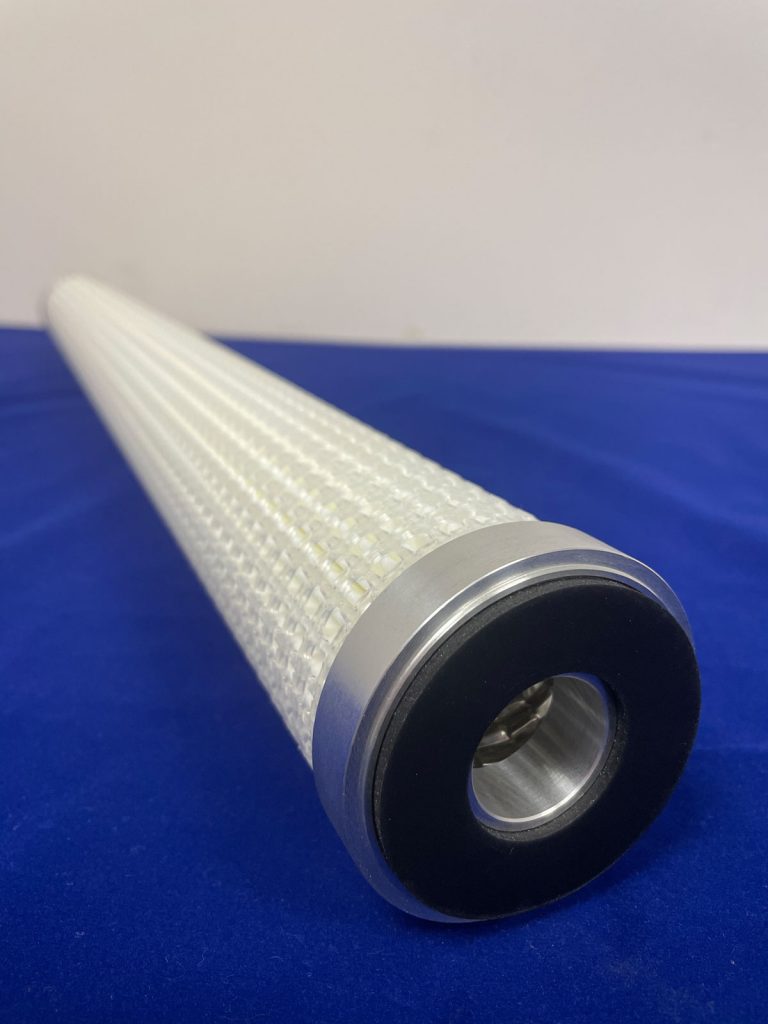

Finally developing a combination membrane media with additional structural integrity and customised seals to combat the chemicals nature to deform the common materials. The primary media structure being of a glass pleat with secondary and tertiary elements to target the unreacted elements to a 1micron level with 99.95% efficiency, to meet the client requirement, all encased in a mesh for clean handling, cored with stainless steel for structural integrity and capped with aluminium for seal support.

Key Features

In house material testing and compatibility analysis

Reactive and agile UK based manufacturing

Material knowledgebase and history

Tenacity

*Image of glass pleat filter cartridge

Customer Benefits

Ability to stock hold without perishable constraint

Consistency in product for supply to wholesale and market

Increased productivity

Production supported with standard batch maintenance

Easy, quick and clean changeouts with minimal tools and protective equipment

Waste product that is contained and easy to dispose of within existing waste channels