While designing and installing industrial filtration systems, one crucial decision is whether to utilize filter housings with filter bags or filter cartridges. While both are widely used in a vast range of industries and applications, they each function in quite diverse ways to achieve different outcomes and performance.

Rosedale Products is not only the world’s largest independent but an industry leading technology developer within liquid filtration systems and waste minimization products. We are here to help you determine if a filter bag housing or filter cartridge housing is best suited to your application.

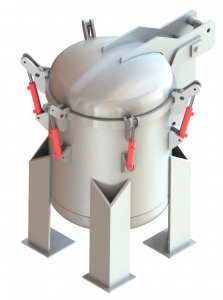

Filter Bag Housings

Also known as strainer vessels, a filter bag housing is a casing around a fabric filter bag in a liquid stream. The filter bag intercepts the contaminants, particulates, or other impurities within the housing or vessel. The purified liquid can then continue through the filtration system. As the bag filter within is easily changed, costs are saved by not having to replace expensive equipment.

Benefits of Filter Bag Housings

Rosedale Products filter bag housings are easy to open without any special tools or equipment so that the filter media can be cleaned or replaced with ease. Filter bag vessels typically experience low pressure drops and are usually permanently piped housings. They’re easy to customize to your system, coming in single filter housings, multi-basket, and multiplex designs. Filter bag housings are generally more effective than filter cartridges when it comes to filtering out larger solids and are regularly used as pre-filters to cartridge filters.

Industrial Applications for Filter Bag Vessels

Bag Filter housings support industrial-grade filters throughout the filtration process, and they can be found in a wide range of applications and industries. As they can be used so broadly, consider the following factors as you choose a filter bag housing:

- Maximum pressure and temperature

- Chemical and physical composition

- Type of duty

- What needs removal

- Maximum flow rate

All these variables will impact the exact filter bag housing requirement for your application.

Filter Cartridges

Filter cartridges are used to capture contaminants and remove particles from water or other industrial liquids. Unfiltered or pre-filtered liquid enters the filter cartridge and is dispersed. Any contaminants are caught while allowing the filtered liquid to continue passing through the filtration system. They can be made of various materials, including stainless steel, and can include resins, composites, and natural minerals capable of targeting dissolved compounds to fit your exact application

Benefits of Cartridge Filtration Systems

Filter cartridges are uniquely versatile as they have considerable flow capabilities. Cartridges for filtration systems are generally clean and easy to maintain, making them a good option for applications where cleanliness is a top concern. Due to the cartridge construction, filter cartridges can be used for surface, depth, or compound removal filtration. Cartridges for filtration systems are particularly effective at filtering small particles and can provide exceptionally high dirt load capabilities.

Industrial Applications for Filter Cartridges

While versatile, cartridge filters are suited and used throughout many industries. They are particularly useful within food and beverage and pharmaceutical applications where hygienic conditions must be constantly maintained. Cartridge filters are also recommended for any industrial application where liquid purification is your most critical priority.

Additionally, cartridges for filtration systems are often used in other processing or manufacturing applications, including:

- Water purification

- Cosmetics

- Pharmaceuticals

- Electric utilities

- Hydraulic fluids

- Bulk chemicals